A car horn is an essential safety feature of your vehicle, providing a vital means to alert others on the road. However, when it stops working, it can pose significant risks.

Understanding the typical issues and how to fix them is crucial for all drivers. This guide covers everything you need to know about diagnosing and repairing a car horn located in the steering wheel.

What is a Car Horn and How Does it Work?

A car horn is an electrical device that produces a loud sound when you press the horn button, usually located on the horn on the steering wheel. It consists of a diaphragm, a coil, and contacts that work together to create sound when an electric current passes through them. When you press the horn button, a circuit is completed, allowing current to flow from the battery to the horn, causing it to sound.

How Long Should a Car Horn Last?

Typically, a car horn should last the lifespan of the vehicle. However, various factors such as environmental conditions, frequency of use, and electrical issues can affect its longevity. Regular maintenance and prompt troubleshooting can prolong its operational life.

What Causes Car Horns to Stop Working?

Several reasons could cause your car horn not working or car horn sounds weak. Below, we will explore common causes and the steps to fix them.

Failed Horn or Horn stopped working

One of the most straightforward reasons a horn may stop working is that the horn itself has failed. Over time, the diaphragm and other components within the horn can wear out.

Wiring Woes

Issues with wiring can also cause your horn to malfunction. Wiring problems can arise from wear and tear, corrosion, or accidental damage.

Burnt Horn Fuse or Bad Relay

A burnt-out fuse or faulty relay can disrupt the electrical flow to the horn. This is one of the more common and easier-to-fix issues.

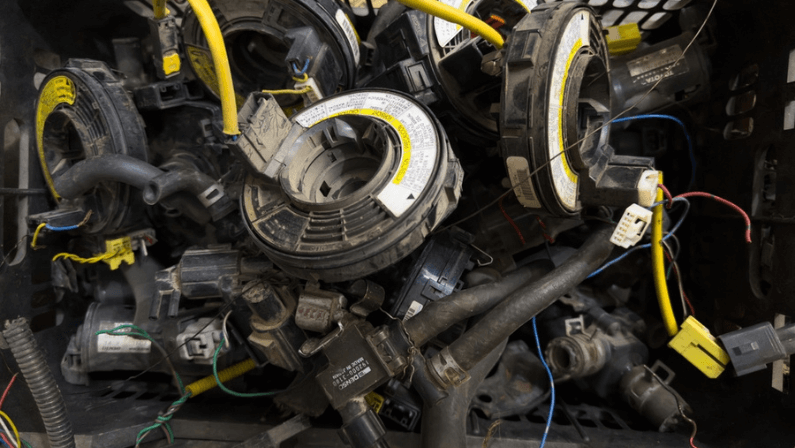

Airbag Clock Spring Issue

The airbag clockspring allows the electrical circuits of the airbag and horn to maintain a connection while the steering wheel is turning. If it fails, the horn may stop working.

Steering Wheel Button Problem

The horn button itself may be the issue, either due to wear and tear or electrical problems within the steering wheel horn assembly.

How Do You Diagnose Horn Problems?

Diagnosing horn problems involves a systematic approach to identify the root cause of the issue.

1. Check the Fuse

One of the first things to check is the horn fuse. Locate the fuse box in your vehicle and find the horn fuse. If it’s blown, replacing it may solve the problem.

2. Inspect the Wiring

Next, inspect the wiring that connects the horn to the power supply. Look for signs of wear, corrosion, or any obvious breaks in the wiring.

3. Test the Horn

Remove the horn from its mounting point and connect it directly to the battery. If it sounds, the problem lies elsewhere in the system.

4. Troubleshoot the Horn Button

Check the horn button by using a multimeter to measure continuity when the button is pressed. If there’s no continuity, the button itself may need replacement.

5. Consult a Professional

If the problem persists after checking these components, it might be time to consult a professional mechanic for a more detailed diagnosis.

How Do I Check the Horn Relay?

The horn relay is another critical component that may need inspection.

1. Locate the Horn Relay

Find the location of the horn relay in your vehicle’s fuse box or relay panel.

2. Test the Horn Relay

Use a multimeter to test the relay. Follow your car’s service manual for the exact procedure to ensure accurate results.

3. Check the Relay Connections

Ensure that all connections to the relay are secure. Loose or corroded connections can hinder its performance.

Why Is It Important to Test the Horn Power Supply?

Testing the power supply is crucial for diagnosing electrical problems related to the horn.

1. Power Supply Verification

Verify that electricity is reaching the horn by using a multimeter to check the voltage at the horn connection.

2. Electrical System Integrity

Testing the power supply helps ensure that your vehicle’s electrical system is working correctly and that there are no broader issues.

3. Troubleshooting Efficiency

Accurate testing of the power supply allows for more efficient troubleshooting, saving time and potentially costly repairs.

By following these steps, you can diagnose and fix most issues related to your car horn located in the steering wheel, ensuring your vehicle remains safe and compliant with road regulations.

How Do I Determine if the Horn Itself is the Issue?

Diagnosing whether the horn itself is the root cause requires a few straightforward tests and inspections. These steps will help you confirm if the horn component itself is defective or if the problem lies elsewhere in the system.

1. Direct Power Test

Performing a direct power test involves connecting the horn directly to the vehicle’s battery to see if it produces sound.

- Procedure:

- Remove the horn from its mounting position.

- Use jumper wires to connect the horn terminals directly to the battery terminals.

- If the horn sounds, the issue is likely not with the horn itself.

- If the horn does not sound, it may need to be replaced.

2. Visual Inspection

A visual inspection can reveal obvious signs of wear or damage.

- Procedure:

- Examine the horn for physical damage, such as cracks or corrosion.

- Check for any loose or disconnected wires.

- Corrosion around the connections could indicate a poor electrical contact.

3. Comparison with Known Working Horn

Comparing your horn with a known working horn can help to isolate the problem.

- Procedure:

- Borrow a working horn from another vehicle or use a spare.

- Connect the known working horn to the wiring of your vehicle.

- If the borrowed horn works, the issue is likely with your original horn.

Why Should I Seek Professional Help for Diagnosing Horn Issues?

While some horn issues can be resolved with basic troubleshooting, there are situations where professional assistance is advisable. Knowing when to seek help can save time and ensure the issue is properly addressed.

1. Expertise and Experience

Professional mechanics have the expertise and experience to diagnose complex electrical problems.

- Benefits:

- They can quickly identify issues that may not be apparent to the average vehicle owner.

- Experienced professionals have dealt with similar problems before, providing efficient solutions.

2. Specialized Equipment

Mechanics have access to specialized tools and equipment that can diagnose and repair horn issues accurately.

- Advantages:

- Using the right tools ensures a precise diagnosis.

- Professionals can perform more thorough testing, which might require equipment not commonly found in household garages.

3. Safety and Legal Compliance

Fixing horn issues professionally ensures that your vehicle remains safe and legal to operate.

- Importance:

- Faulty repairs can lead to further issues, compromising the safety of your vehicle.

- Ensuring your car horn works properly keeps you compliant with road safety regulations, avoiding potential fines or penalties.

FAQs

When should I replace my car horn?

You should replace your car horn if it fails to sound during a direct power test, shows significant physical damage or corrosion, or if it becomes unreliable.

How do you fix a car horn that won’t work?

Fixing a non-functional car horn often involves checking and replacing fuses, inspecting wiring, testing the horn and relay, and ensuring the horn button in the steering wheel is functioning correctly.

Can you drive a car if the horn doesn’t work?

While it is possible to drive a car without a working horn, it is not advisable. The horn is a crucial safety feature, and its absence can make it challenging to alert other drivers in an emergency situation.

How do I know if my horn relay is broken?

You can determine if your horn relay is broken by testing it with a multimeter for continuity or swapping it with a known working relay of the same type. If the horn works with the replacement relay, the original relay is likely faulty.

Do car horns need to be replaced?

For car honk not working, they need replacement if they no longer function correctly, usually due to wear and tear, electrical issues, or physical damage. Regular testing and maintenance can extend their lifespan.

Why does my car horn only work sometimes?

Intermittent operation of a car horn can be caused by loose connections, a failing relay, worn-out horn button contacts, or issues with the airbag clockspring.

Is it expensive to fix a car horn?

The cost to fix a car horn can vary widely depending on the cause of the issue. Simple fixes like replacing fuses or relays are relatively inexpensive, while more complex electrical repairs or component replacements can be costlier.

A Functional Car Horn

Understanding how to diagnose and repair a car horn issue in the steering wheel ensures your vehicle remains safe and compliant with road regulations. While some fixes are straightforward, others may require professional help, particularly for complex electrical issues. If you are in Houston and require expert assistance, Status Automotive & Collision is an excellent choice for professional and reliable service.

Remember, maintaining a functional car horn is not just about convenience but a critical aspect of road safety. Don’t hesitate to seek the help needed to keep your horn in working order.